AIR POLLUTION CONTROL

Air pollution control system is used in modern industrial plants to minimize the excess release of harmful chemicals and dust solids into the atmosphere, as ambient air consists of liquids, gas, and most surprisingly, solids.

Over the years, air pollution has become critical and engineers have invented various methods of air pollution control. Many of these methods involve the use of air pollution control equipment.

With our technology partner, AYS will be able offer different air pollution control systemsas shown below that will be designed based on individual plant requirements in compliance to the local authorities from the Department of Environment DOE.

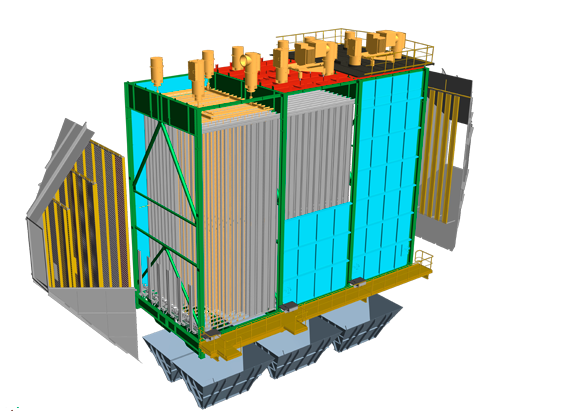

Electrostatic Precipitator ESP

Electrostatic precipitators with their countless areas of application remain the most economical system for the removal of dust from industrial gases.

Operating costs are reduced due to low energy consumption, and the cost of maintenance and spare parts is very low. In addition, the life expectancy of an electrostatic precipitator usually exceeds that of the upstream production units, such as kilns, mills, driers and coolers.

Electrons are emitted from discharge electrodes which have been charged with a rectified negative high voltage. These electrons migrate to the collecting electrodes. As the electrons accumulate on the dust particles, the latter become negatively charged. The electric field transports them to the earthed collecting electrodes where they are deposited.

Mechanical rapping equipment cleans the collecting electrodes by means of periodic rapping. The robust RS electrodes and the maintenance-friendly design are only two of the ELEX electrostatic precipitator’s main characteristics.

BAG AND CARTRIDGE FILTER

Filter-media is selected depending on the application. A large array of different filter media is available to cover all applications.

The filter-bags are assembled over a supporting cage and are fixed either on the raw or the clean gas side of the support floor. Maintenance is convenient and economical.

The housing can be supplied in round or modular design. In the modular design individual modules can be combined so that it is possible to achieve a filter surface of up to 2000 square meters. Round housings range from 560mm to 2600mm in diameter. Depending on the diameter and bag length, a filter surface of up to 250 square meters is possible.

LSF bag-filters are robust filters with fully automatic pulse cleaning systems suitable for many industries. The filters are used for the recovery of dry dust and for cleaning process gases.

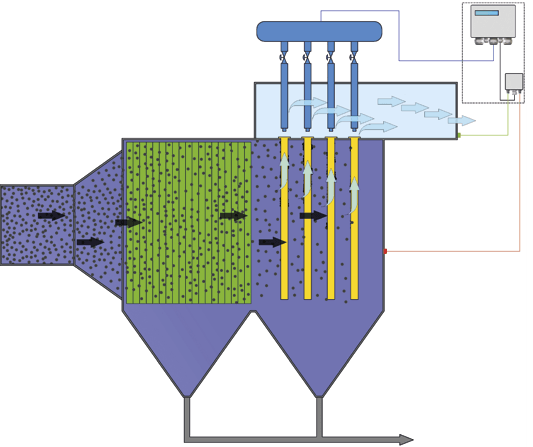

Hybrid Filter

Thanks to the synergy resulting from the combination of a practically maintenance-free electrostatic precipitator with a bag house; very good pure gases can be achieved at low energy costs.

One electrostatic precipitator field alone is capable of eliminating at least 90 % of the dust volume at very low energy consumption. Thanks to the ionisation and agglomeration effect in the electrostatic precipitator section, pressure loss in the fabric filter is reduced by up to 40 %. As only 10 % of the cleaning performance is carried out by the fabric filter, the use of compressed air is significantly reduced, which consequently significantly extends the life and maintenance intervals of the filter media. As a result, overall efficiency is higher than with fabric filters.

This concept is especially adapted to the modernisation of old electrostatic precipitators where the existing housing and the first electrostatic precipitator field can still be used.

The ELEX custom-designed and manufactured hybrid filter systems reflect decades of experience and continuous research to achieve the best possible outcome.

Hybrid filters are used most frequently in the cement industry and for boilers, fired with coal or biomass.