LATEST NEWS

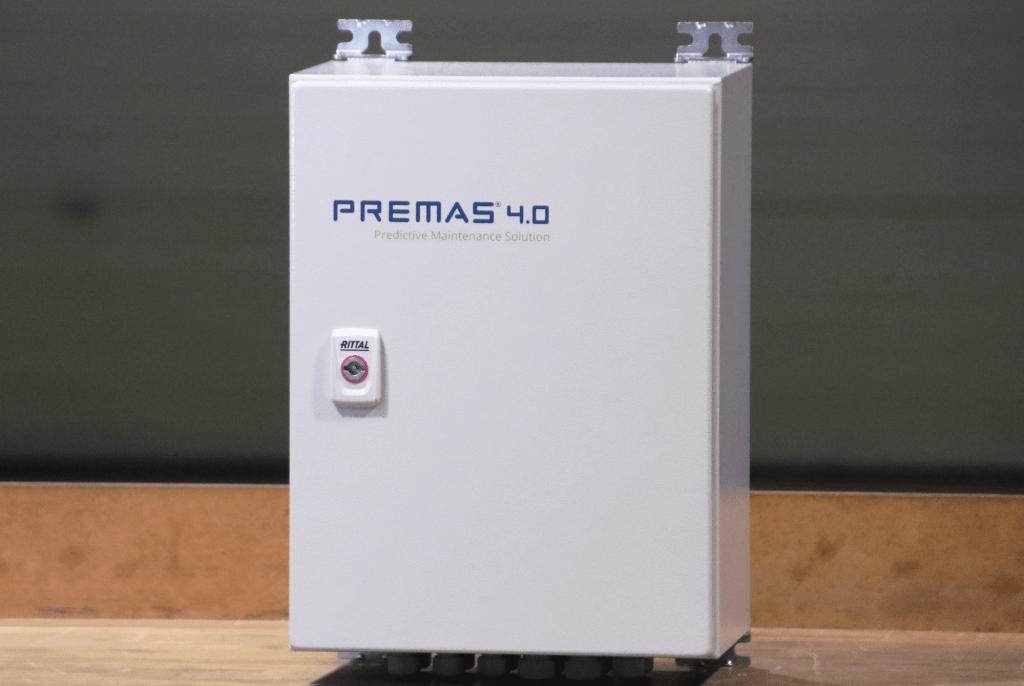

With effect of 30 June 2021, KoWey GmbH & Co. KG, Kamp-Lintfort (Germany) has ceased its business operations worldwide. AUMUND Fördertechnik GmbH takes over the After Sales Service from KoWey (Germany) and from KCT Engineering (India) on all machinery including original spare parts, retrofits and conversions and site services with regards to the bucket elevators and conveying systems supplied worldwide. AUMUND PREMAS® Services for preventive and predictive maintenance are highly recommended for all installed KoWey machines to check on the operating and machine conditions to avoid premature equipment breakdown, causing production disruption. For further support or information, all former KoWey customers are invited to contact us for further details.

AUMUND Asia Ltd, located in Hong Kong China, is acting in the Asia Pacific Area and sells AUMUND, SCHADE and SAMSON equipment in all kinds of key industries such as Cement, Mining & Minerals, Chemical and Fertilizer Industry, Ports & Terminals and many others more. Synergies within the AUMUND Group of companies consistently lead to successful outcomes: In May 2020 AUMUND Hong Kong won an order from PT Asahimas Chemical, Java/Indonesia, for the New Generation of STORMAJOR®. The project was technically supported by SAMSON Materials Handling Ltd/UK leading product company in the AUMUND Group for mobile bulk handling solutions. The pre-assembly of the STORMAJOR® takes place in the workshops of AUMUND Foerdertechnik GmbH, Rheinberg/Germany. The delivery is planned for December 2020.

Cost-effective and short delivery time. From now AUMUND Machinery Technology (Beijing) Ltd offers worldwide two types of SAMSON Eco Hoppers designed on a new economical and technical concept by saving all advantages and benefits of the product. The standardization of the Eco Hopper type EH45 (inlet 4.5x4.5m) and type EH60 (inlet 6.0x6.0m), available on rails, wheeled or fixed, enables a more effective assambling of the components, a lower price level and shorter delivery times. EH 45 and EH 60will be produced in China and can be ordered worldwide from AUMUND China directly. The SAMSON Eco Hopper series applies a variety of dust and environmental control technologies, such as crosswind turbulence reduction system, Flex-Flap dust seal system, integral cartridge dust filter Units, etc. It is an economical and ecologically sensitive solution fulfilling all needs for the efficient import of dry bulk cargoes. The Hoppers are designed to suit the characteristics and flow properties of virtually any bulk material such as Clinler, Bauxite, Limestone, Iron Ore, Gypsum, Slag, Coal, and many others. Rates to 3000 tons per hour may be achieved subject to the grab crane performance. The open size and height of top shroud, the angle of lower hopper, the thickness and the type of wear material are all customized for the client’s specific product and process.

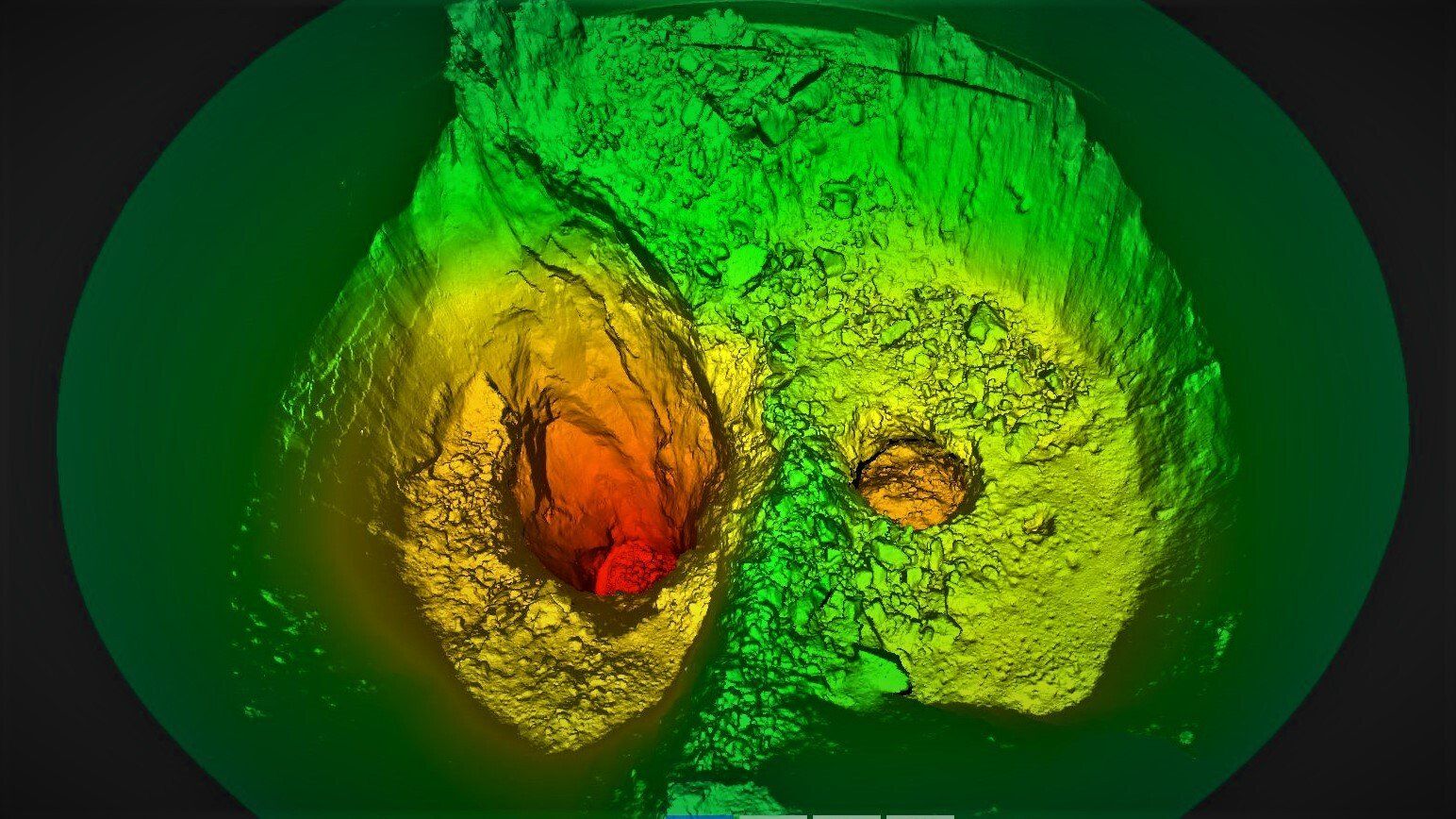

1 Introduction Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on the other hand, ball mills whose share decreased to just over 10%. Gebr. Pfeiffer SE supplies stand-alone MPS coal grinding mills as well as complete coal grinding-drying systems. Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas atmosphere. System configurations cover grinding plants with temporary storage of the pulverized coal in silos (for cement plants, or in blast-furnaces for steel plants, etc.) and installations with direct injection into the combustion system (for power generating plants). For over 40 years, the MPS mills for power stations have been manufactured under license of Hitachi Power Europe GmbH (formerly Babcock Borsig AG), headquartered in Oberhausen, Germany. .

The successful partnership between AUMUND France and AUMUND China has resulted in large orders for AUMUND in Algeria for two new cement plants at Zahana and Bechar. Decades of customer support, in particular strong after-sales service by AUMUND France in Algeria, as well as the close relationship of AUMUND China to the Sinoma Group, have culminated in this achievement. The two orders together comprise 26 Belt and Chain Bucket Elevators, two Bucket Apron Conveyors, ten Pan Conveyors and ten Drag Chain Conveyors.The Société des Ciments de Zahana (SCIZ) plant, which has a capacity of 4,500 tpd, is near Oran, around 450 km from the capital Algiers. Here three Chain Bucket Elevators with centre distances ranging from 22.5 to 34.9 m, and capacities from 50 to 220 tph, will be used to convey cement and clinker. Eleven Belt Bucket Elevators (cc 22.5 -116.1 m) will convey raw meal, cement and clinker with capacities between 190 and 680 tph.

Some of the leading cement producers in West Africa are companies which belong to the globally operating LafargeHolcim Group. AUMUND S.A.R.L. in Paris, France, is the responsible AUMUND Group entity for this region. AUMUND France has supplied a complete solution package to LafargeHolcim Côte d’Ivoire for clinker discharge from a new silo with a capacity of 75,000t, and commissioned the equipment in the summer of 2020 despite restrictions caused by the coronavirus pandemic.