BULK MATERIAL CONVEYING

(MECHANICAL)

Through the partnership with the industry experts for bulk material conveying, AYS ENGINEERING is capable to design, supply and

commission bulk material conveying systems.

Our innovative product and reliable solution make us a competent supplier in the bulk material handling industy.

BELT BUCKET ELEVATOR

- Aumund Belt Bucket Elevator for vertical conveying of bulk materials

- Designed for high capacity up to >2,300m3/hr

- Lifting heights up to 175m

- Material temperature handling up to 130 deg C

- High tensile strength of steel-reinforced belt with additional longitudinal cross ropes to resist the bucket fixation tearing

- Equipped with segmented friction lining for all drive pulleys for easier replacement without opening up the belt

- Direct feeding of material into buckets for low bucket wear

- Continuous material take up & discharge via the buckets design & close bucket spacing

- Ultimate strength of the clamping connection via cable to cable connection

- Outstanding service life with low maintenance for continuous operation

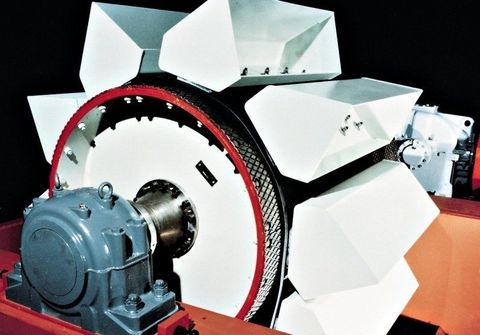

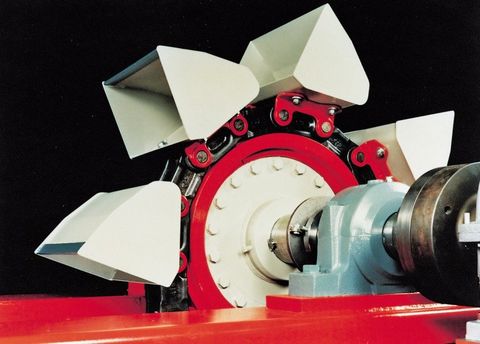

CHAIN BUCKET ELEVATOR

- Aumund Chain Bucket Elevator

- With conveying capacity up >2,200m3/hr

- Lifting heights up to 90m

- Heavy duty central chain with plate link design

- High quality forged chain contributes to outstanding service life – ideal for continuous operation

- Easy bucket fixing with angular brackets

- Equipped with segmented drive ring for easy maintenance

- Anti-friction bearing concept for easy exchange

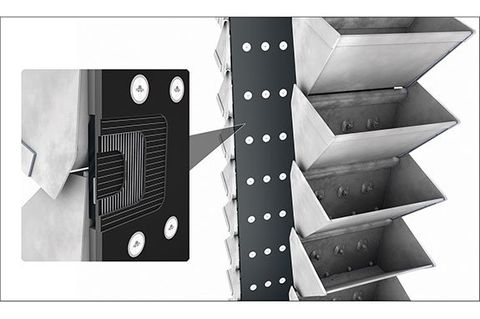

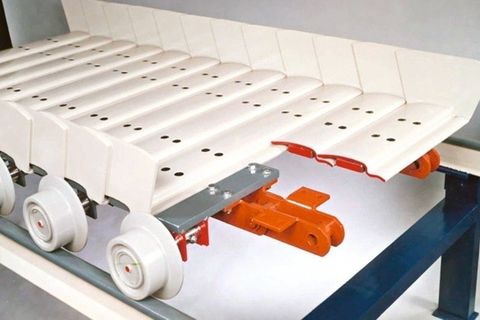

PAN CONVEYOR

- AUMUND Deep Drawn Pan Conveyor

- Suitable for conveying hot materials up to 700 deg C

- Designed for conveying with up to 60 deg inclination

- Designed for conveying heights up to 96m

- Capacity exceeding 1,000 tons per hour

- Heavy duty AUMUND chain with high breaking load at 290 – 3,000kN per-strand

- Profiled steel pans for high rigidity and minimal spillage

- Lifetime lubricated rollers for low maintenance

- Modular system allows interchangeable of parts

APRON WEIGH FEEDER

- Integration of Aumund pan conveyors & process weighing electronics into one unit of feeding and weighing conveyor

- To ensure gravimetric feeding of raw material with high weighing accuracy

- Various selection of pan conveyors for integration, e.g : Arched Plate Pan Conveyor & Deep Drawn Pan Conveyor

- Arched Plate Pan Conveyors type BPB is most ideal for cohesive material handling

- Deep Drawn Pan Conveyor type KZB is suitable for coarse bulk material with fines, e.g : clinker, granulated blast furnace slag, petroleum coke

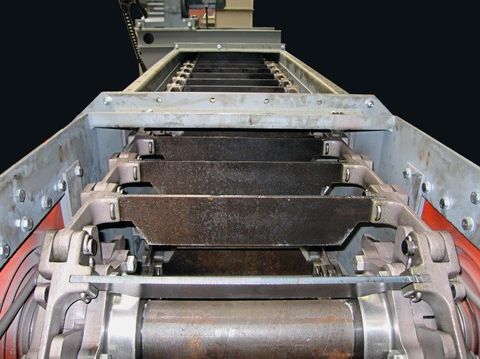

ARCHED PLATE CONVEYOR

- Specially designed for bunker conveying of moist & sticky materials

- Fitted with heavy duty caterpillar chain with extreme high breaking strength

- Chain carrying rollers designed for high impact loads

- With regulation of the unloading capacity via adjustable rotational speed drive

- High capacity up to 11,000 tons per hour

- Ability to handle uncrushed raw materials with edge length up to 2,000mm

DRAG CHAIN CONVEYOR

- Aumund Drag Chain Conveyor

- For conveying, distributing and reclaiming powdery, coarse, abrasive and high moisture bulk material

- Single & double-strand forged chain depending on application

- Hardened forged chain & sprocket with tempered teeth at 58 HRC

- Conveying distance up to 50m

- Dust tight conveying of dusty material

- Flexibility arrangements with horizontal & inclined positions

- Designed to convey & distribute bulk material to multiple locations via shut-off gates for all intermediate discharges

- Ability to handle wet materials (moisture content from 25-35%) via stainless steel lining

SURFACE FEEDER

- AUMUND Surface Feeder

- Application as material receiving conveyor for bulk materials e.g coal, aggregates, clinker direct, alternative fuel

- No deep pits required

- No underground hoppers & expensive civil works needed

- Flexibility in installation location

- Handling of sticky & wet material

- Fast truck discharge

- No risk of bridging or blockage

- Minimal dust generation

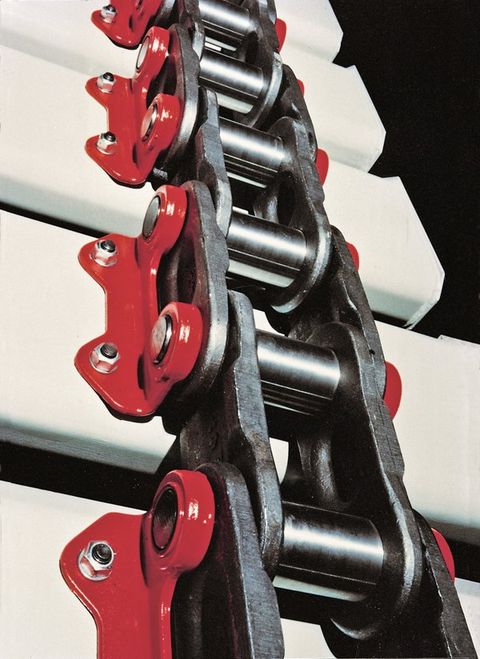

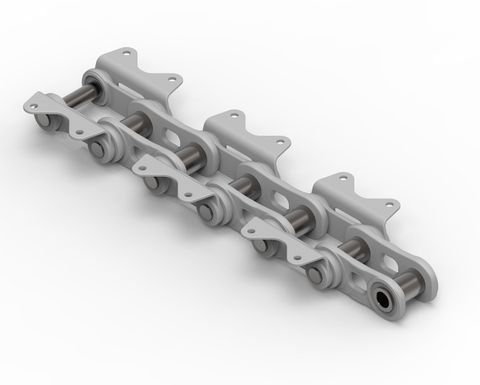

CHAIN AND SPROCKETS

KettenWulf Chains have gained a reputation as the longest lasting, most reliable chains available for all ranges of bulk material handling applications.

Fatigue Strength:

- Smooth surface of pitch holes

- Exactly defined, high press fits between pins, bus hings and link plates

- Heat treatment for optimal strength and maximum breaking loads

Wear Resistance:

- Selection of the best materials for appropriate heat treatment

- Optimal hardening penetration through induction or case hardening of pins and bushings

- Providing longer service life and less downtime

Reliability:

- Highest accuracy of hole dimensions and surface quality

- 100 % inspection of incoming materials through spectrometer analysis to ensure strict compliance to KettenWulf material standards

- All processes according to ISO 9001 and ISO 14001

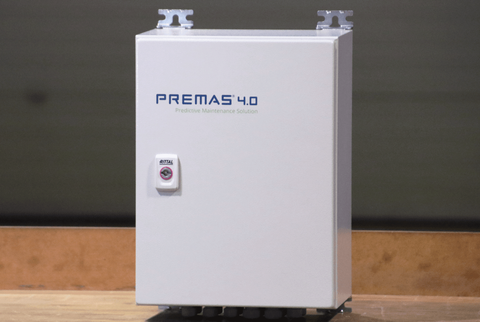

PREMAS®4.0 BUCKET ELEVATOR MONITORING

CONiQ® consists of three main elements to measure, analyze and interpret condition monitoring data more effectively than any other system on the market.

- Machine measurement with 6-dimensional MEMS (microelectromechanical system)

- Exciter measurement using piezoelectric accelerometers

- Oil temperature with Pt100

The 6-dimensional MEMS (three-dimensional acceleration and linear and three dimensional rotation and velocity) are a unique feature of CONiQ® and are essential to detect any motion change. Measuring mechanical vibration (piezoelectric sensors to monitor bearings, gears etc.) and machine movement separately (6D MEMS to monitor load, springs, intermediate shaft etc.) enables more accurate detection of actual or potential faults.

The sensors and other measurement devices send data to the processing unit located beside each machine, which calculates state variables and measures these against preconfigured initial and limit values.

These variables can be easily monitored on the display panel. Data is stored on the processing unit and can be downloaded to a PC for historical trend analysis across multiple variables (orbit displacement and acceleration, amplitude and envelope spectrum etc.) using CONiQ® View software.