SILO SCAN TECHNOLOGY - XYLOSCAN

Bulk storage silos are essential process equipment in the cement and building materials industry used for various bulk material storage & blending process. The silos are often being used continuously 24/7 over the years but are always neglected in the annual shutdown maintenance plan due to limited diagnostic tools in the industry to check the operation and efficiency of storage silos.

The diagnosis of material flow inside the silo during discharge is utmost important to understand the operating condition and discharge efficiency of the silo to predict potential breakdown and loss of storage volume. Many plant operators underestimated the importance of diagnosis for silos. But when the breakdown finally happens affecting the silo operation, this could result in huge financial losses due to production shutdown, material dispatch issues, loss of sales and loss of storage volume.

WHO ARE WE?

IBAU HAMBURG based in Germany is well known for their trademark Central Cone Storage Silos and has over 45 years of worldwide experience in engineering solutions for bulk storage silos, pneumatic conveying systems, bulk terminals and ship-unloaders.

Specialized in Silo Technology, IBAU HAMBURG has innovated the XYLOSCAN technology for 3D silo survey with the objective to increase silo efficiency, operation, maintenance and to provide solutions to many common problems of bulk material storage systems.

XYLOSCAN is the future of silo diagnostics!

DO YOU HAVE?

- Silos with low storage volume?

- Material discharge problems in silos?

- High dead stocks and lumps in silos?

- Non-uniform material flow?

- Discrepancy in material stock level?

- Cost over-run for silo cleaning?

- Silo maintenance issues due to lack of diagnostic tools?

- Civil and structural failures?

XYLOSCAN TECHNOLOGY WILL SOLVE YOUR PROBLEMS

WHAT ARE THE APPLICATIONS?

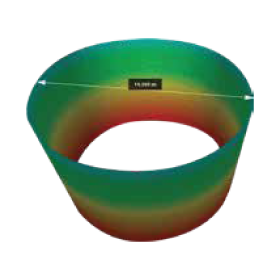

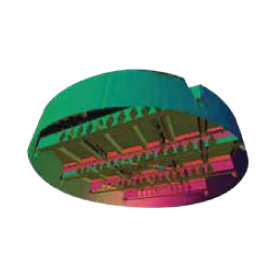

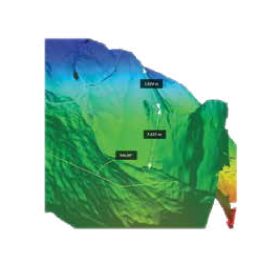

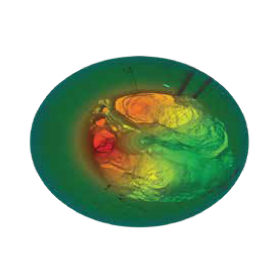

- 3D surface mapping for material distribution and flow pattern analysis

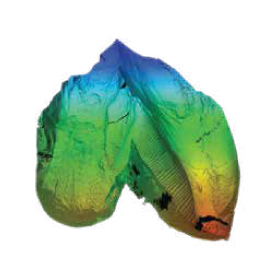

- Deadstock and coating area identification

- Technical audit for silo operation and maintenance

- Material stock “area” and “volume” calculation

- 3D material model to approach silo cleaning

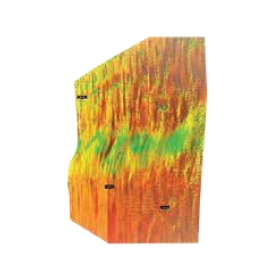

- Forensic engineering for structural failures

- Reverse engineering for design upgrading works

- As-built 3D scan model

- Virtual Reality for training