PORT HANDLING EQUIPMENT

Sea Transportation of Bulk Materials is a major component of global trade. Marine Ports worldwide require highly reliable and efficient material handling systems to unload and load bulk materials in an efficient and seamless handling process.

For the ports and terminals industry, AYS together with our technology partners provide a complete range of port handling equipments for bulk materials for all kinds of vessels with different capacities.

Some of our most frequently loaded materials are cement, coal, fertilizers, grain, and food commodities sugar, flour and many more.

We strive to provide our customers with the latest technology and know-how in the port handling equipments.

SHIPUNLOADER

- IBAU Shipunloader

- Suitable for wide range of bulk materials eg. cement, gypsum, fertilizer and other powdery materials

- Unloading via mechanical conveying screw

- Low power consumption 0.4-0.5kwH per tonne as compared to vacuum suction system

- Various vessel sizes and unloading capacities:

- Up to 5000dwt vessel with 300tph unloading capacity

- Up to 15000dwt vessel with 300tph unloading capacity

- Up to 60000dwt vessel with 800tph unloading capacity

SHIPLOADER

AMECO Bulk Shiploaders are able to load Bulk carriers up to 120,000 DWT at rates of up to 3000 m3/h. We have worldwide operating references handling urea, grain, coal, clinker and sugar with several decades of perfect work and reduced maintenance.

Our objective is to implement a robust and simple design for our Shiploaders, hence inducing minimal and easy maintenance costs for our customers.

AMECO’s Bulk loading Shiploaders include the following:

- Tripper Car located on the Jetty Conveyor with its chute to the feeding Conveyor

- Loading spout that can be either a telescopic pipe equipped with a belt thrower system or a banana chute, orienting the flow of material

- Loading spout that can be a telescopic pipe equipped with kick-in / kick-out device and banana chute

- Telescopic cascade

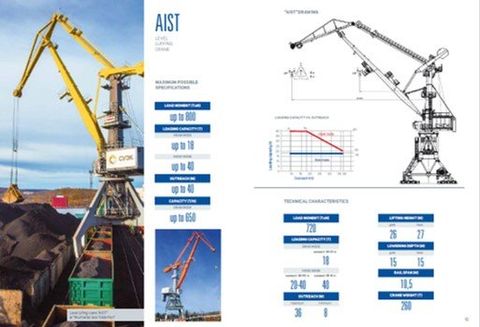

LUFFING CRANE

The company specializes in projecting, producing, mounting and servicing maintenance of heavy-duty hoisting equipment for ports, transport terminals, shipyards, hydraulic facilities and industrial enterprises.

In 2005, “SMM” first supplied Murmansk Sea Trade Port with the ”AIST” portal crane. It was delivered as part of the program of import phase-out for home production of handling equipment that can compete with the best foreign analogues.

Today more than 150 items of heavy lifting machines are being successfully used not only in Russia but also all over the world.

”SMM” delivers projects in regions with harsh climate placing great focus on ecological issues and environment preservation. The company strives to achieve constant refinement of products and safety.

In 2018-2019 ”SMM” launched 2 manufacturing units enabling the company to form vertical integration including all the steps of production of lifting machines from drafting to the finished product:

- Manufacturing unit “SMM-Tyazhmash“

specializing in production of steel structures and equipment for transport, mining, iron and steel and nuclear industries

- Manufacturing unit “SMM-Electro“

specializing in engeneering and production of automated control systems for electric drives, power distribution units and hydraulic equipment.

ECO-HOPPER

AUMUND Eco-Hopper, a dust controlled grab unloading hopper is an economical and ecological solution fulfilling all needs for the efficient import of dry bulk cargoes.

The hoppers are designed to suit the characteristics and flow properties of virtually any bulk material:

- Clinker

- Copper Concentrates

- Slag

- Sulphur

- Gypsum

- Biomass (Woodchip etc.)

- Limestone

- Bentonite

- Iron Ore

- Nickel Ores

- Bauxite

- Soda Ash

- Coal

- Others

Rates to 5000 tons per hour may be achieved subject to the grab crane performance. Unloading with traveling hoppers has the advantage of being a very flexible solution. The throughput of the terminal can be increased by just adding one or more hoppers, provided the collecting belt conveyor and the subsequent handling equipment are designed for future capacity increase with larger vessels.