INDUSTRIAL PACKAGING SYSTEM (FINE POWDER)

AYS ENGINEERING with our technological partners are the specialist in providing packaging solutions in the area of filling dry bulk material into industrial bags of all types, paper or plastics in different bag weights and configurations.

We are able to provide solutions from manual, semi-automatic and up to full automatic packing plants according to industrial specifications.

We strive to provide our customers with the latest technology and know-how in the packaging industry.

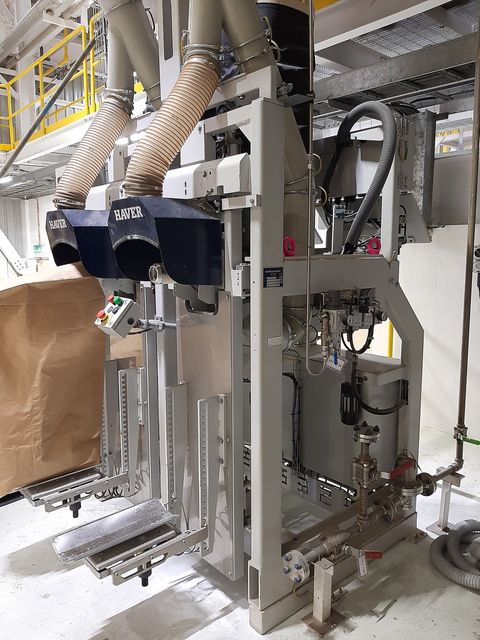

VALVE BAG PACKER

- Suitable for valve bags (Paper, PE and PP)

- 1 Spout, expandable up to 4 Spouts

- Capacity up to 1200 bags per hour

- Suitable for bag weight range 5 to 50kg

- Precise weighing accuracy

- Modular design

- Available in impeller, air, pump type filling system

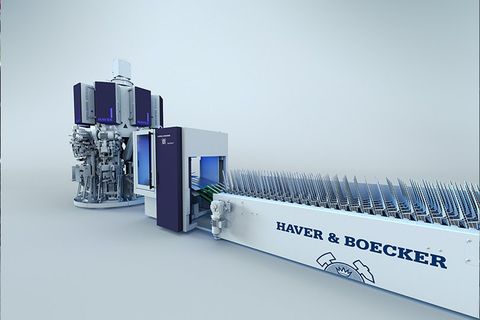

VALVE BAG PACKER (FULL AUTOMATIC)

- Full automatic packaging system

- Consist of bag placer, filling module, bag discharge conveyor, control and operating system under one housing

- Suitable for valve bags (Paper, PE and PP)

- 1 Spout, expandable up to 4 Spouts

- Capacity up to 1200 bags per hour

- Suitable for bag weight range 5 to 50kg

- Fully encapsulated to reduce dust pollution and noise

- Fast setup and installation

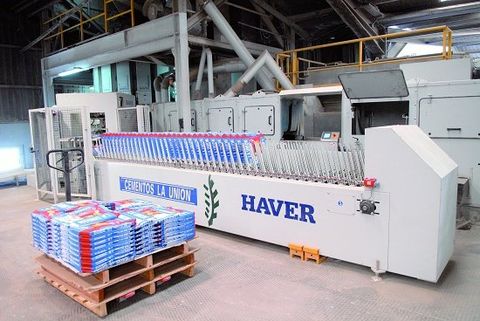

ROTOPACKER

- Based on proven HAVER Rotopacker Technology

- Suitable for valve bags (Paper, PP)

- 4 Spouts, expandable up to 16 Spouts

- High capacity up to 5000 bags per hour

- Suitable for bag weight range 25 to 50kg

- High weighing accuracy

- Modular design, easy maintenance

- Available in impeller and air type filling system

- Expandable with automatic empty bag applicator RADIMAT

AUTO BAG APPLICATOR

- Based on proven HAVER Rotopacker Technology

- Suitable for valve bags (Paper, PP)

- High application capacity up to 6000 bags per hour

- Suitable for bag size range 25 to 50kg

- Increase production efficiency and utilization rate

- Reduce manpower costs

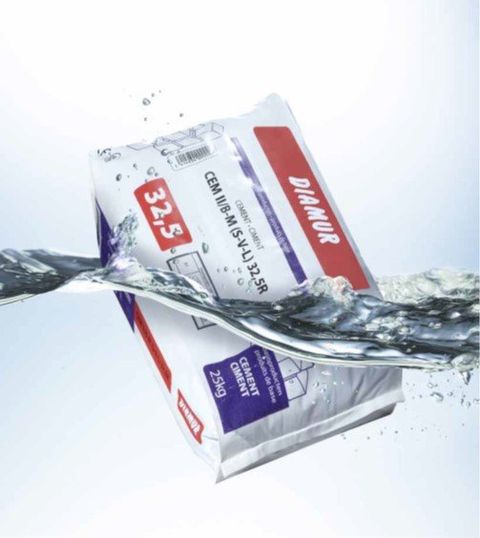

ULTRASONIC SEALING

- Tight, clean and attractive packaging

- No material leakage from valve bag

- Precise weight accuracy

- Longer shelf life

- Dust free environment at packing plant

- Lower maintenance

- Temper / theft proof

FORM FILL SEAL FFS

- Form-Fill-Seal FFS for powder material

- Applicable for PE tubular film with side gussets

- 1 Spout, available up to 12 Spouts

- Suitable for bag weight range 5 to 50kg

- High weight accuracy

- WATERPROOF > long shelf life

- CLEAN > attractive packaging

- DURABLE > high tear strength of PE film

- FLEXIBLE > instant change of bag weights

FIBC FILLING

- Manual and Full Automatic System

- Suitable for standard FIBC bags in the market

- Suitable for bag weight up to 1500kg

- High weight accuracy

- Swivelling filling head for highest ergonomics

- Modular design, static and movable system

- Available with vibrating bottom for compaction

- Different dosing system available for all range of material

QUATTRO SYSTEM MONITORING

Make your systems transparent with QUAT²RO Monitoring, you have your production in view at any time and from anywhere. By using the QSM, your maintenance and plant personnel can stay on track of your equipment's maintenance schedule. Whether it's inspecting or replacing a belt, cutting knife, suction cup or any other component, use ourQUAT²RO System Monitoring to keep yourself up to date with daily or weekly emails. You can receive alerts when a maintenance schedule is past due, and using the web portal, you can check the maintenance schedules from any device and from anywhere you have internet access. Stay ahead of the issues and reduce any unexpected downtime.