INDUSTRIAL PROCESS FAN

Large and special process fans from our technology partner, Venti Oelde Germany are used in almost all key industries. They are the “heart” of industrial plants and processes, as they are mostly in use 24/7, for example in the cement and steel industries as well as in the chemical industry and refining plants, in power stations and waste incineration plants.

Venti Oelde guarantees operation reliability through technical competence and recognized quality over the 90 years of experience. Our services range from process design, engineering, supply, installation and commissioning of process fans. Our designs are durable, low-noise and easy to maintain. Each fan is calculated and constructed for its specific use based on process parameters. If required, centrifugal fans can comply with the strict American Petroleum Institute Standards API 560 and 673.

LARGE AND SPECIAL FANS

Venti Oelde is one of the world’s leading providers of large and special fans for the cement, lime and gypsum industries.

They are in use throughout the complete production process chain, from firing and cooling, grinding and separating to dust removal. Our fans work under arduous conditions, depending on the operating point and application, they fulfil various functions. The large fans are confronted with acceleration and centrifugal forces of varying strength, as well as with vibrations of differing strength and direction. They must withstand changes in temperature as well as corrosive media attacks and abrasive dust and also fulfil the regulations for noise control.

Venti Oelde engineers are acquainted with the complete production process. They select suitable materials for the individual components, dimension them according to the application and adjust them to each other. Reliable wear prevention, high efficiency and long service lives are the main objectives of our planning and production.

HIGH PRESSURE FAN

Venti high-pressure fans combine intelligent technology with outstanding quality. Venti high-pressure fans can be used in almost limitless ways, but especially as pressure-increase fans in industrial processing and chemical engineering, for the fluidisation of powders, dusts and granulates in the cement, paint and plastics industry, as forced-draft fans for firing plants, as combustion air fans in industrial furnaces, glass-melting pans and smelting plants. Our high-pressure fans work over pressure ranges from 30 to 250 mbar.

They are the first choice where safe operation and high availability are required alongside optimum efficiency and low energy consumption.

Venti high-pressure fans are compact and strongly built. Flat performance curves permit wide variations in the flow volume at a constant pressure increase.

Venti manufactures high-pressure fans in a strong, welded construction. The fan scroll of the single inlet centrifugal fan is arranged in front of the motor pedestal so that it can be rotated, which means the fan casing can be positioned in 45° steps.

HOT GAS RECIRCULATION FANS

Venti high-pressure fans combine intelligent technology with outstanding quality. Venti high-pressure fans can be used in almost limitless ways, but especially as pressure-increase fans in industrial processing and chemical engineering, for the fluidisation of powders, dusts and granulates in the cement, paint and plastics industry, as forced-draft fans for firing plants, as combustion air fans in industrial furnaces, glass-melting pans and smelting plants. Our high-pressure fans work over pressure ranges from 30 to 250 mbar.

They are the first choice where safe operation and high availability are required alongside optimum efficiency and low energy consumption.

Venti high-pressure fans are compact and strongly built. Flat performance curves permit wide variations in the flow volume at a constant pressure increase.

Venti manufactures high-pressure fans in a strong, welded construction. The fan scroll of the single inlet centrifugal fan is arranged in front of the motor pedestal so that it can be rotated, which means the fan casing can be positioned in 45° steps.

AXIAL FLOW FANS

Special air cooling in the cement industry

To cool rotary kiln jackets, and for other cooling processes in cement factories, swivel-mounted axial fans blow air onto the outer surfaces. There is a fixed version or there is an option to make the axial fan manoeuvrable. Specially adapted nozzle systems provide an optimum cooling effect.

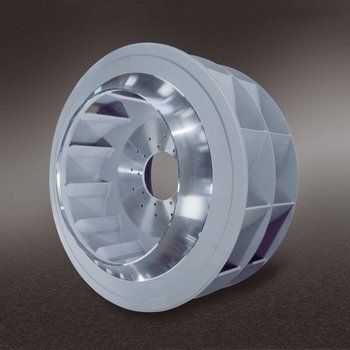

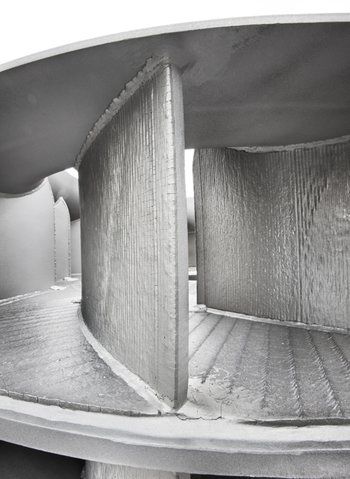

HARDFACING IMPELLER

Fans are often subject to the harshest wear. Abrasive media that is carried in the air flow (e.g. clinker dust, quartz and also corundum, wood and plastic shavings) attack the material.

Wear can render high-quality machine parts inoperative in the shortest time. The resulting costs are considerable. Investing in preventive measures is cost effective.

Venti Oelde uses various measures to prevent abrasion to impellers and inner casing walls through friction and impact. Such protective measures are decided on as early as during the design of our fans. Suitable materials, high-precision machining and optimal blade geometry effectively increase service life.

PROCESS FAN AUDIT

The services that Venti Oelde provides start with the first contact and extend right through to support during regular operation. From projecting to the planning phase and from engineering to the installation, you have a personal contact the whole time.

We see conscientious planning as the basis for efficient operation. Venti Oelde configures fans according to the individual requirements of the customer and on the basis of our own appraisal and measurements. We also determine the potential for optimization in existing plants individually.

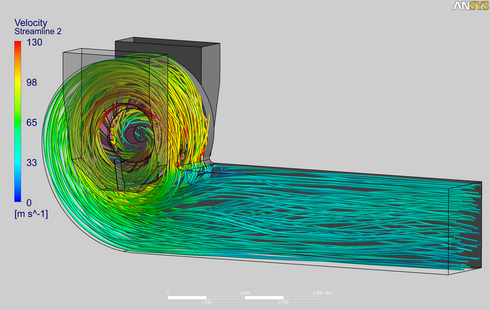

We use our know-how in aerodynamics, acoustics and vibration engineering to constantly improve and optimize our fans and systems.