PULVERIZED COAL HANDLING

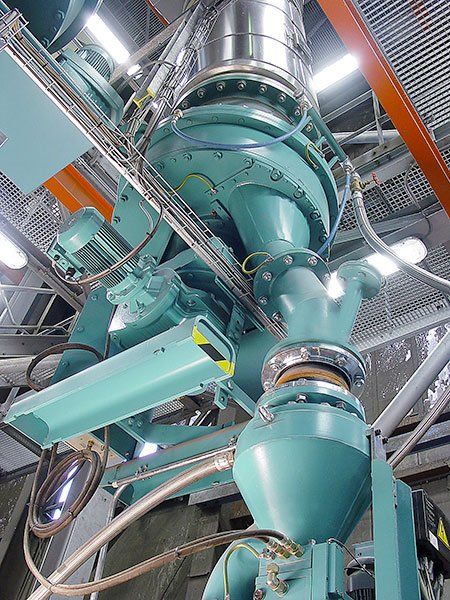

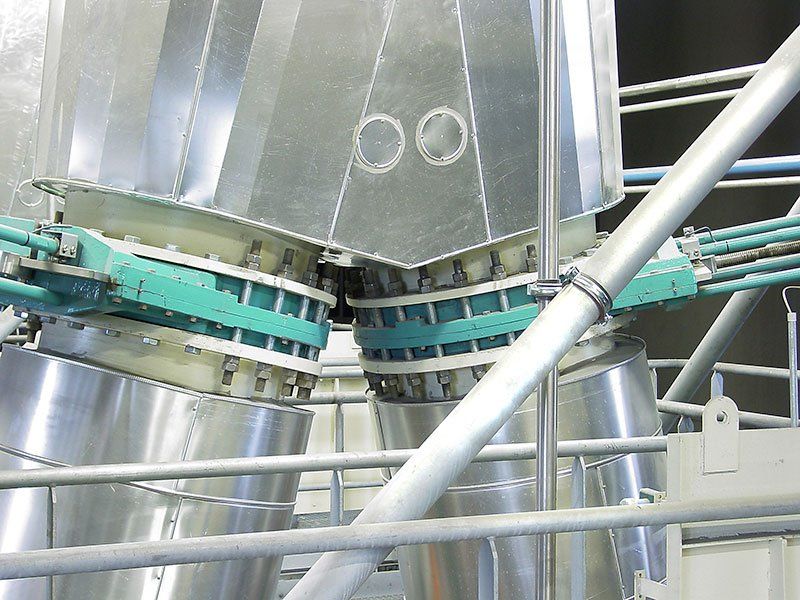

MULTICOR® K and MULTICELL

Coal dust feeding

Pulverised coal feeding is a critical process equipment that requires accuracy, quality and maximum reliability for continuous production. The parameters are based on the interplay of overall system engineering, material discharge, feeding and pneumatic material transport.

Optimal pulverised coal feeding in three steps

Perfectly matched system components are a basic requirement for optimal three-step pulverised coal feeding. This is realised in a pressure-proof mass-flow feed system using the Coriolis principle with a horizontal star feeder.

1. Pulsation-free silo extraction

Schenck Process Silo Engineering stands for mass flow at the beginning of the process chain. The large silo outlet and agitation system which is integrated into the horizontal star feeder ensures the homogenisation of the material and its pulsation-free discharge from the silo.

2. Exact measurement – excellent feeding performance

The material flow is measured quickly and precisely using the Coriolis principle. It functions without being affected by any external influences. The MULTICELL horizontal star feeder’s speed control performs the direct mass flow measurement. This ensures that the actual feed rate exactly corresponds to the specified nominal value.

3. Pulsation-free transport

Our engineering ensures the ideal layout of the pneumatic conveyor line. The from the feeder to the burner. The exact design pressure and intake volumerequired amount of air and the conveyor cross-section are calculated to ensure optimal transport of the fuel of the blower are also determined.